Have you ever wondered how Tesla and other automakers manufacture electric vehicles (EVs) so quick? Their secret weapon is 3D product design engineering. Let us discuss why this technology is a game changer for making electric vehicles better, faster, and more efficient.

Table of Contents

ToggleImproved Design And Weight Management

3D product design can help create complex automotive parts that would be difficult to create using traditional methods. One of its main advantages is the ability to reduce weight without weakening the part. This is especially important for EVs, as lighter vehicles can travel a greater distance on a single battery charge.

An important advantage is that instead of assembling several small parts, one solid part can be made. It’s like assembling something from a single component rather than several small parts. This not only makes the parts more durable, but also reduces the overall weight of the vehicle.

Keeping Batteries Cool And Safe

Electric car batteries are similar to our mobile phones, and 3D design engineering has helped develop clever cooling systems to keep the batteries at the right temperature.

Engineers can design special cases and cooling channels that would not be possible using traditional manufacturing methods.

It is like designing a custom-made water bottle with built-in cooling, but more complex and think of it not for drinks, but for car batteries. Such a design would make the battery last longer and perform better.

Test Ideas Faster Than Ever Before

Remember when you had to build something to see if it would work? The 3D design allows engineers to test their ideas on the computer before they build anything physical. This is like a video game where you can build and test parts of a car.

If something does not work properly, they can fix it with a few clicks instead of spending weeks building new parts. In other words, new electric cars can go from idea to reality much faster than before.

Save Money The Smart Way

Starting a new car company used to cost billions because it required huge factories and expensive tools. 3-D design and printing have completely changed this game. Now, even small companies can make auto parts without the need for huge factories.

This is especially useful when making just a few thousand parts instead of millions. This allows new companies to enter the market with innovative ideas without having to struggle for funding.

Make Parts When And Where You Need Them

With a 3D design file, parts can be made anywhere in the world with the right printer. In other words, companies do not need huge warehouses full of spare parts. They can simply store their designs on a computer and print out the parts when their customers need them. They can save space, reduce waste, and get replacement parts faster.

Better Collaboration

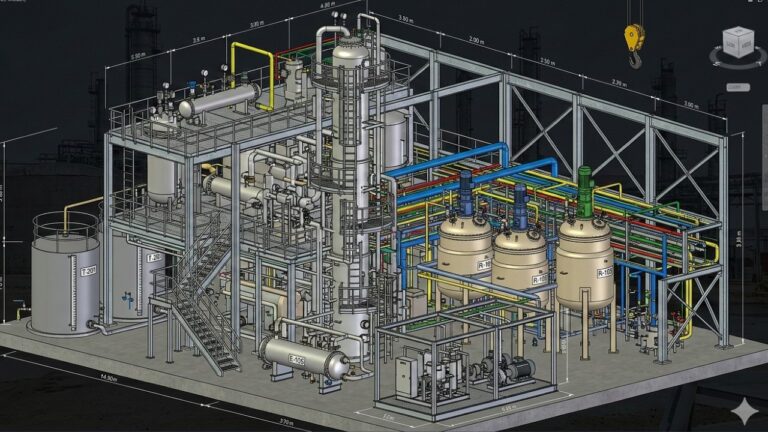

Modern 3D design tools are like Google Docs for engineers, multiple people can work on the same design at once. While the electrical engineer designs the battery, the mechanical engineer can design the car body.

This teamwork ensures that everything fits perfectly and works well. This is like having a virtual room where everyone building the car can work together, even if they are in different parts of the world.

Looking To The Future

As electric vehicles become more common, the importance of 3D design engineering will only increase. 3D design engineering is helping to make electric vehicles

- More efficient (can drive farther)

- More affordable (lower development costs)

- Better quality (designs can be thoroughly tested before manufacturing)

- More innovative (new ideas can be tested quickly)

Final Considerations

Turn your electric vehicle concept into reality with 3D-Ace’s comprehensive modeling services. We offer everything you need to accelerate your EV development from detailed product modeling and digital twins to AR/VR solutions.

Our expertise spans Metaverse 3D modeling, 3D character modeling, 3D game solutions, environmental modeling, AR/VR modeling, digital twin creation, and product modeling.

Together we will create the future of electric vehicles. Contact us today to see how our 3D design expertise can move your EV project forward.