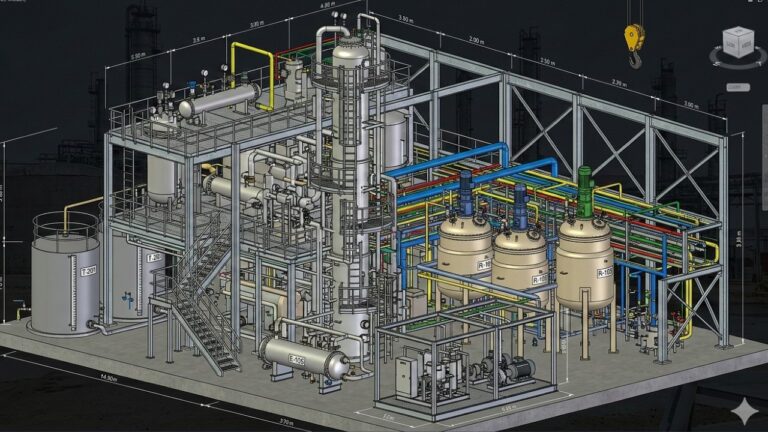

Today’s competitive market urges businesses to find innovative and efficient pathways to superior product development. 3D Engineering services transform concepts into functional, manufacturable and market ready products. These services reduce development timelines, minimize expenses, and accelerate market entry by leveraging product design engineering, 3D CAD Modeling, and rigorous prototype testing.

We explore how 3D Engineering Services enhance product development across key areas including 3D Product Rendering, CAD Modeling, Reverse Engineering, and Value Engineering.

Top Benefits of 3D Engineering Services

1. Product Ideation & Concept Development

Every successful product begins with thorough ideation and conceptualization including:

- Market Research – Identifying unmet needs and opportunities

- Brainstorming – Creating innovative design solutions

- Concept Evaluation – Determining viable design directions

- Prototyping & Testing – Confirming functionality and usability

3D Product Modeling & Rendering Services enable teams to visualize concepts in early stages, validating feasibility before production investments.

2. Industrial Design & Product Engineering

Industrial Design integrates aesthetics with functionality, creating user-friendly and manufacturable products. Product design engineering services emphasize:

- Ergonomics & Usability – Optimizing user experience

- Material Selection – Striking the right balance between cost and durability

- Manufacturability – Designing efficiently for mass production

3D CAD Modeling Services deliver precise simulations that minimize errors and boost efficiency.

3. 2D to 3D CAD Conversion – Enhancing Design Accuracy

Legacy 2D drawings remain common in many industries, but 3D model conversion offers substantial advantages:

- Enhanced Visualization – Realistic three-dimensional representations

- Streamlined Modifications – Quick and accurate design adjustments

- Collaborative Efficiency – Clear communication between multidisciplinary teams

3D CAD Modeling and Design Services guarantee smooth transitions from traditional blueprints to dynamic digital models.

4. 3D Product Rendering – Bringing Designs to Life

3D Product Rendering creates photorealistic visuals that serve multiple purposes:

- Marketing & Sales – Compelling visuals for promotional campaigns

- Client Presentations – Convincing concept demonstrations

- Design Refinement – Early identification of visual flaws

This technology allows businesses to showcase products virtually, eliminating physical prototype expenses.

5. Reverse Engineering & 3D Scanning

Existing products often need improvements or replication. Reverse Engineering delivers solutions by:

- Accurate 3D Scanning – Capturing exact measurements of physical objects

- Digital Model Creation – Developing editable CAD models

- Performance Enhancements – Improving functionality or reducing costs

These capabilities prove especially valuable in machine design where legacy components require modernization.

6. Prototype Testing & Value Engineering

Rigorous 3D Prototype Testing ensures

- Functional Validation – Comprehensive performance assessment

- User Feedback Integration – Identification of ergonomic challenges

- Manufacturing Feasibility – Production efficiency confirmation

Value Engineering simultaneously optimizes costs while maintaining quality by:

- Material and Process Analysis – Identifying cost-effective alternatives

- Efficiency Improvements – Minimizing waste and production time

Conclusion

3D Engineering Services revolutionize product development from concept to manufacturing. Companies will gain competitive advantages through faster development, reduced expenses, and superior results when they implement these 3D CAD Modeling, 3D Product Rendering, Reverse Engineering, and Prototyping. Are you ready to turn your ideas? Contact us about 3D engineering services for your next project.