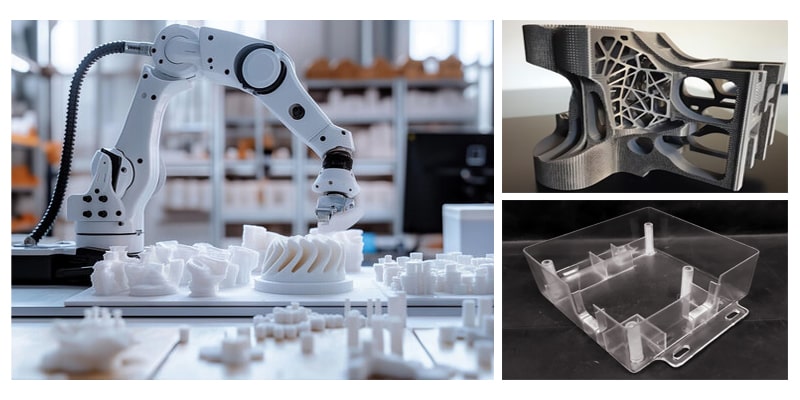

The 3D printing industry is booming with predictions of $34.5 billion by 2028 and 16-25% growth in the next few years. This is because 3D printing is being used across healthcare, manufacturing, cars, electric vehicles, planes, and consumer goods. The more uses the more the market grows.

How 3D Printing Companies Changing the Face of Manufacturing

Faster and More Powerful Printers

Companies have made big improvements in printer speed and performance. In the past 3D printing used to be slow, now new tech has cut print times down. For example, CLIP uses liquid photopolymer and UV light to print continuously not layer by layer. MJF uses multiple liquid binding jets to print fast.

These improvements mean larger and more complex objects can be printed faster, making 3D printing a real option for making things in large numbers. This change opens up new ways for industries to make products more quickly and create custom items efficiently.

New Materials and Their Impact

Top 3D printing companies have also worked hard to create many new materials. 3D printing is no longer limited to basic plastics.

Now we see

- Metals: Titanium, aluminum, and stainless steel are common, especially in airplane and car industries.

- Biomaterials: Used for healthcare, like making skin grafts and cartilage.

- Earth-Friendly Materials: Created to lower environmental damage, good for industries wanting to reduce their carbon footprint.

- Construction Materials: Concrete and building materials are now used for 3D printing buildings.

These new materials have expanded what 3D printing can do, allowing for stronger and more useful objects across different fields. 3D-Ace, one of the leading 3D printing company in Mumbai, excels in offering a wide range of materials including metals, making them a top choice for businesses in India.

Better Precision and Multi-Directional Printing

Improvements have gone beyond speed and materials. Companies have made 3D printing much more accurate by using more advanced computer programs and control systems, developing 5-axis and 6-axis printing, which allows objects to be made from more angles, and creating nano- and micro-scale printing abilities. These improvements let people make very detailed and complex objects with incredible precision.

Impact on Different Industries

Faster printers, new materials, and better precision have turned 3D printing from a special technology into a game-changing tool across many areas.

Some industries benefiting most include

- Aerospace: Making light but strong parts for planes and spacecraft.

- Automotive: Quickly creating custom parts and prototypes.

- Healthcare: Designing personalized implants, artificial limbs, and surgical tools.

- Consumer Products: Allowing mass customization and quick product testing.

Looking Ahead

Several trends will likely shape 3D printing in the future.

- Combining with Artificial Intelligence: Smarter 3D printing systems will optimize printing and choose materials based on instant feedback.

- Focus on the Environment: More emphasis on materials that break down naturally or can be recycled.

- Advances in Biological Printing: Continued progress in creating working organs and tissues, which could change healthcare.

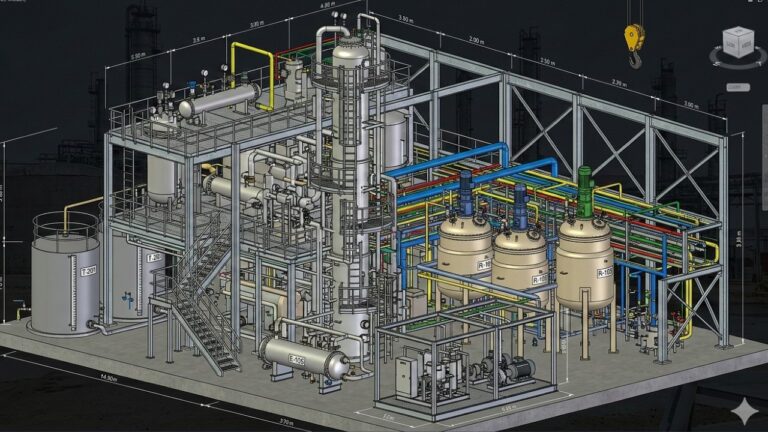

- Digital Connections: 3D printing will play a bigger role in creating digital copies of real-world objects, helping to predict and simulate manufacturing processes.

Final Thoughts

If you are seeking metal 3D printing company in India or the best 3D printing service provider in Mumbai, then, it’s 3D-Ace. We are one of the top 3D printing companies in Mumbai. We offer a range of services and our services including DMLs 3d printing service, custom 3D printing in Mumbai, and 3D metal printing in Mumbai. As one of the top 3D model makers in Mumbai, 3D-Ace is equipped to meet all your 3D printing needs with precision and excellence.