Product Design & Development

Product Ideation & Concept Development

The process of Engineering Product Ideation and Concept Development involves generating innovative ideas and systematically developing them into viable product concepts that can be further refined and brought to market.

This process typically includes several key stages:

- Identifying market needs and opportunities.

- Brainstorming and idea generation.

- Concept screening and evaluation.

- Prototyping and testing.

- Refinement and final concept selection.

Each stage requires collaboration among cross-functional teams, including design, engineering, and manufacturing, to ensure that the final product concept meets customer needs, is technically feasible, and can be produced cost-effectively.

Product Design & Research

In product development, it is crucial to integrate thorough analysis to ensure the final product’s success. This involves understanding user needs, market trends, and technological advancements.

- Development

- Testing

- Implementation

Industrial Design

Is a process of design applied to products that are to be manufactured through techniques of mass production. Product Design is an extensive process of design that is specifically applied to products intended for mass production through various advanced manufacturing techniques. The domain of Industrial Design, which places a strong emphasis on engineering concepts and practical applications, aims to create highly innovative and functional products that not only effectively meet the diverse needs of users but also significantly enhance their overall experiences in a meaningful way.

Product 3D Rendering

Three-Dimensional Product isualization means creating a realistic image or model of a product that looks like it is three-dimensional, allowing you to see it from different angles.

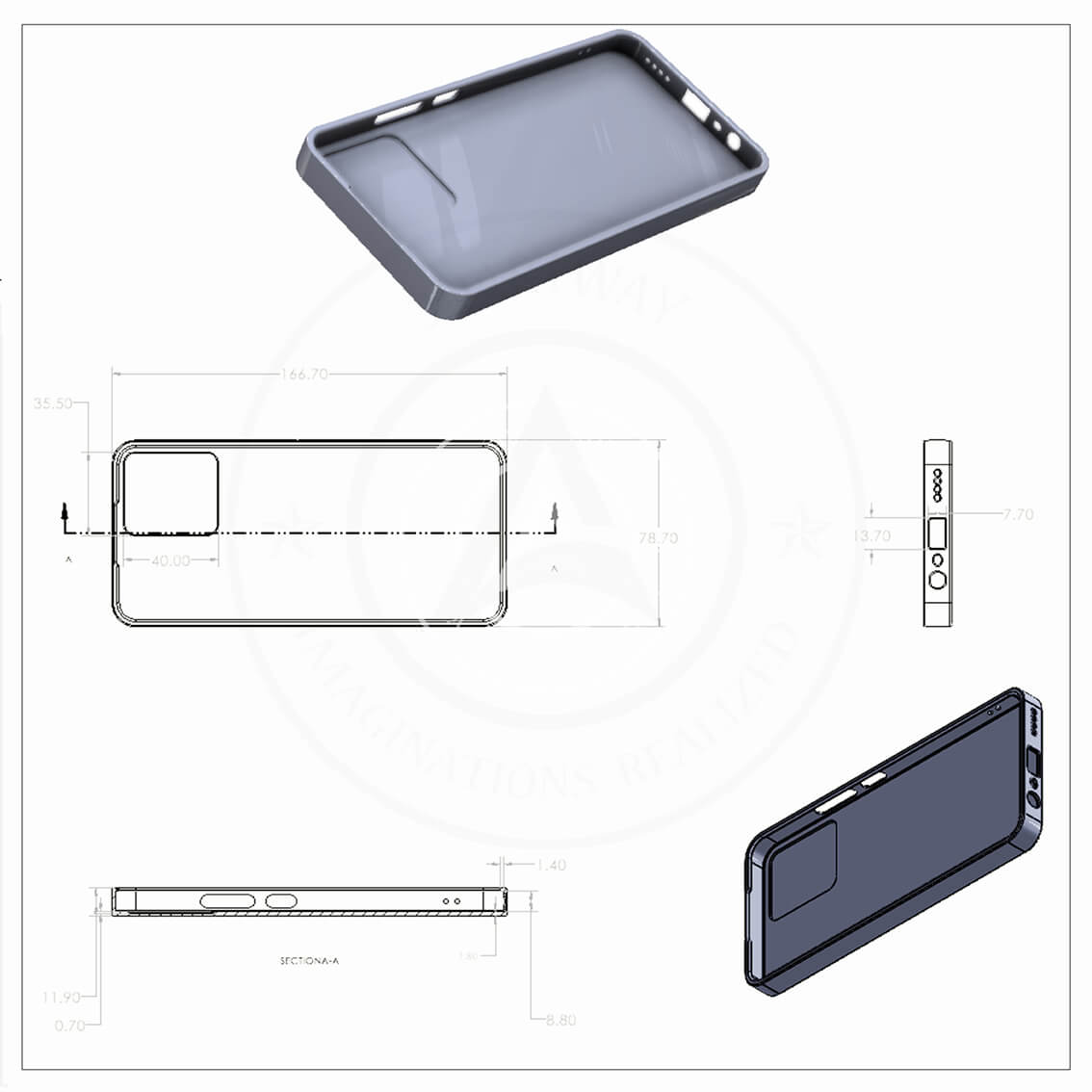

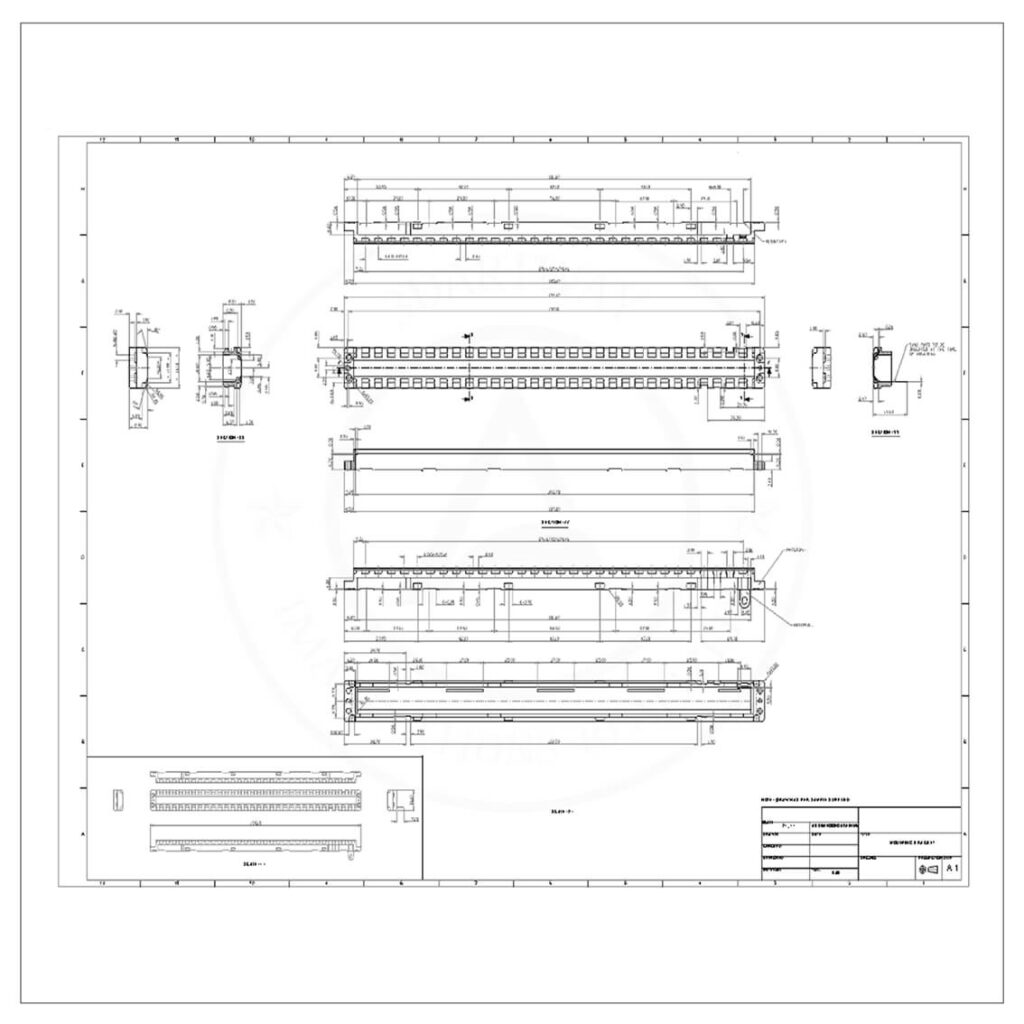

2D & 3D CAD Modeling

Using computers to create detailed drawings and models in both two dimensions (2D) and three dimensions (3D).

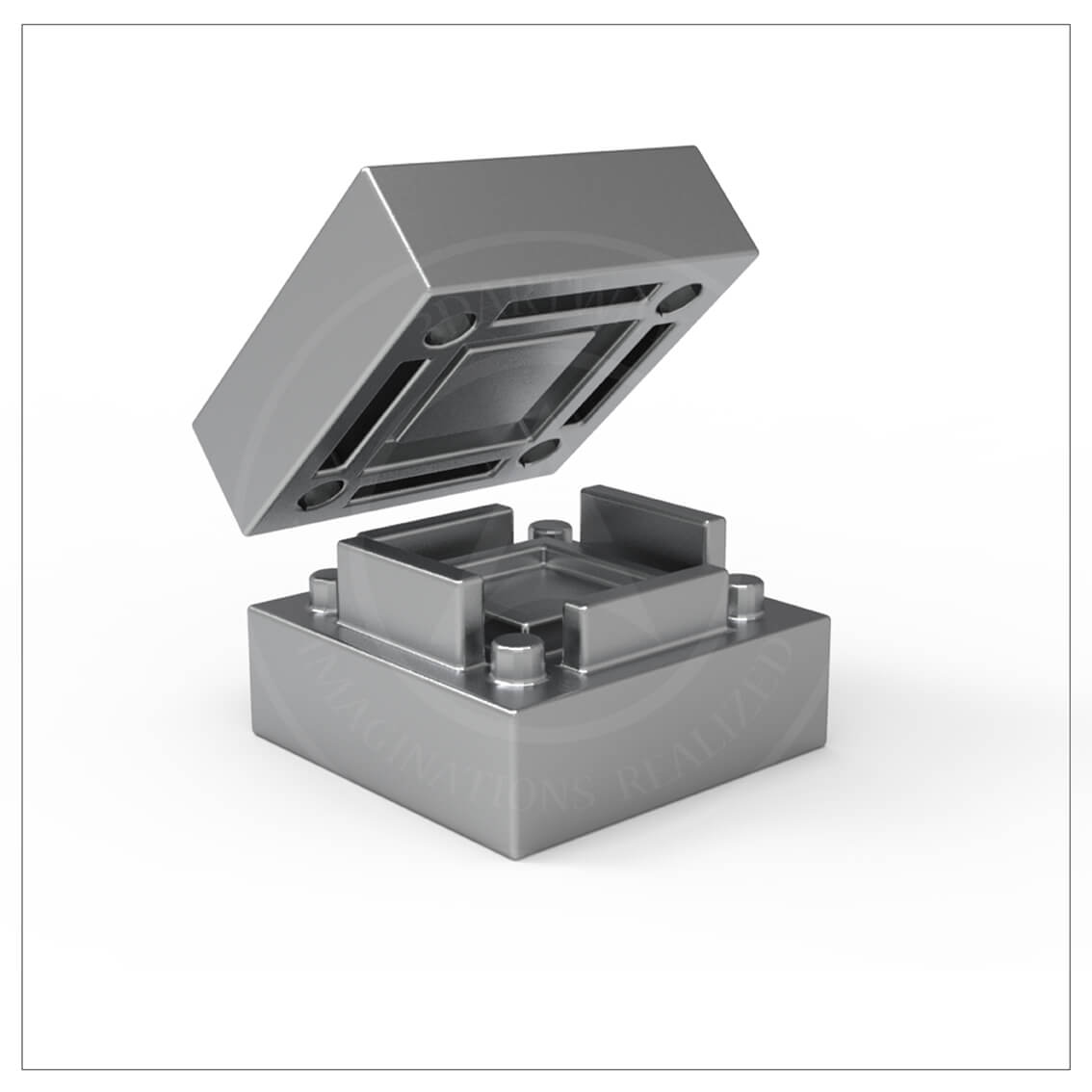

3D Solid Surface Modelling

Advanced Techniques in 3D Solid Surface Modelling for Complex Geometries 3D solid surface modelling means creating three-dimensional objects on a computer. These objects have solid surfaces and can be made of different materials.

2D to 3D CAD Conversion

Conversion of 2D Drawings to 3D CAD Models for Enhanced Visualization and Design Accuracy.

2D to 3D CAD conversion means converting a two-dimensional drawing into a three-dimensional model.

3D CAD Design Assembly

(Working Model)

3D Computer-Aided Design (CAD) Assembly for a Fully Functional Working Model.

Mechanical Drafting

Mechanical drafting means the drawing of technical plans and designs for machines and mechanical systems.

Engineering Services

Machine Design & Manufacturing

Machine Design & Manufacturing encompasses the comprehensive process of conceptualizing, designing, and producing machinery and mechanical systems, integrating advanced engineering principles and cutting-edge manufacturing techniques.

Reverse Engineering – 3D Scanning

Reverse Engineering – Advanced 3D Modelling Techniques This innovative technology enables the detailed and precise capture of physical objects, transforming them into highly accurate digital representations for various applications.

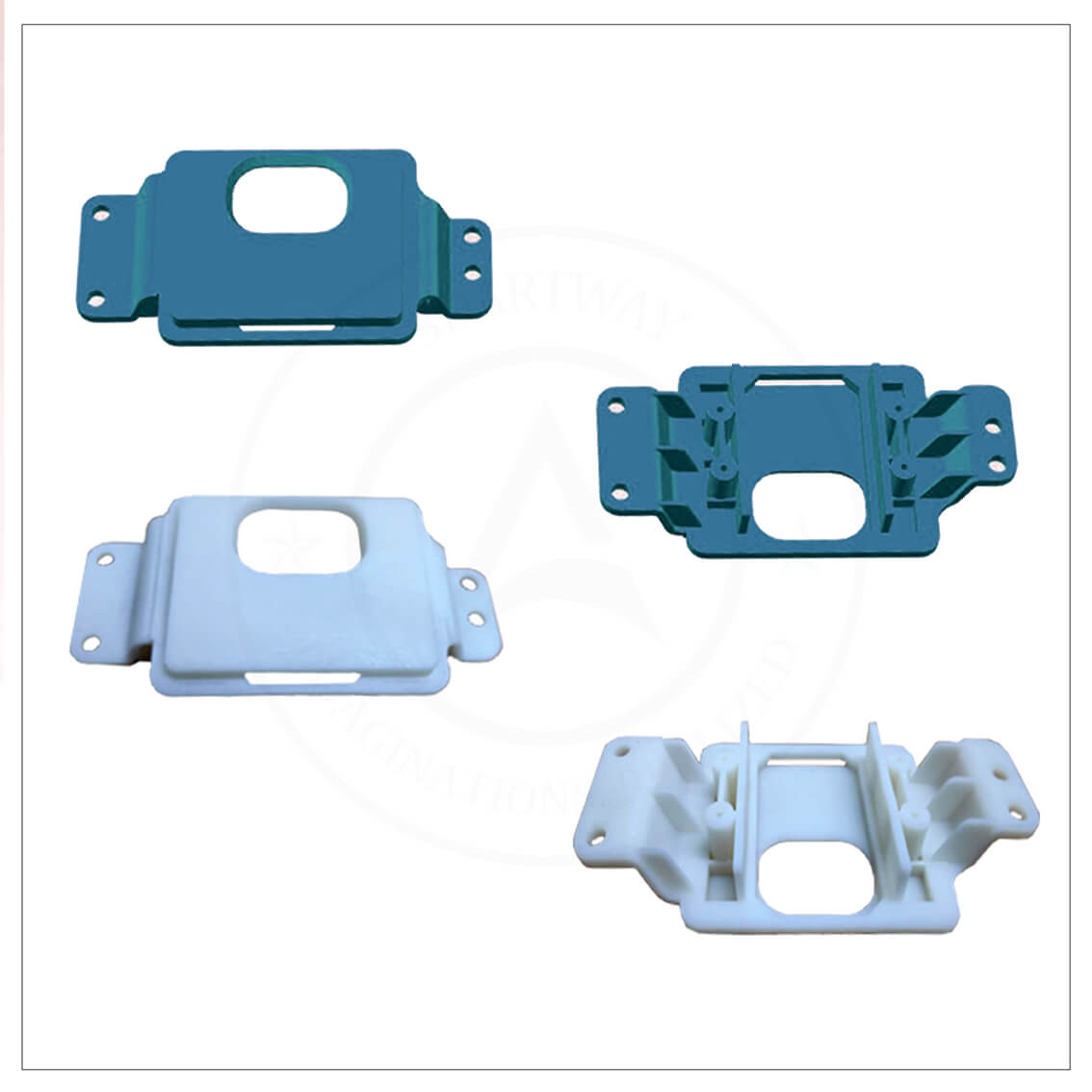

Mold Design Engineering

Mold Design Engineering: The Art and Science of Creating Precision Molds for Manufacturing Implementing innovative techniques to enhance Mold durability and performance

Testing & Optimization

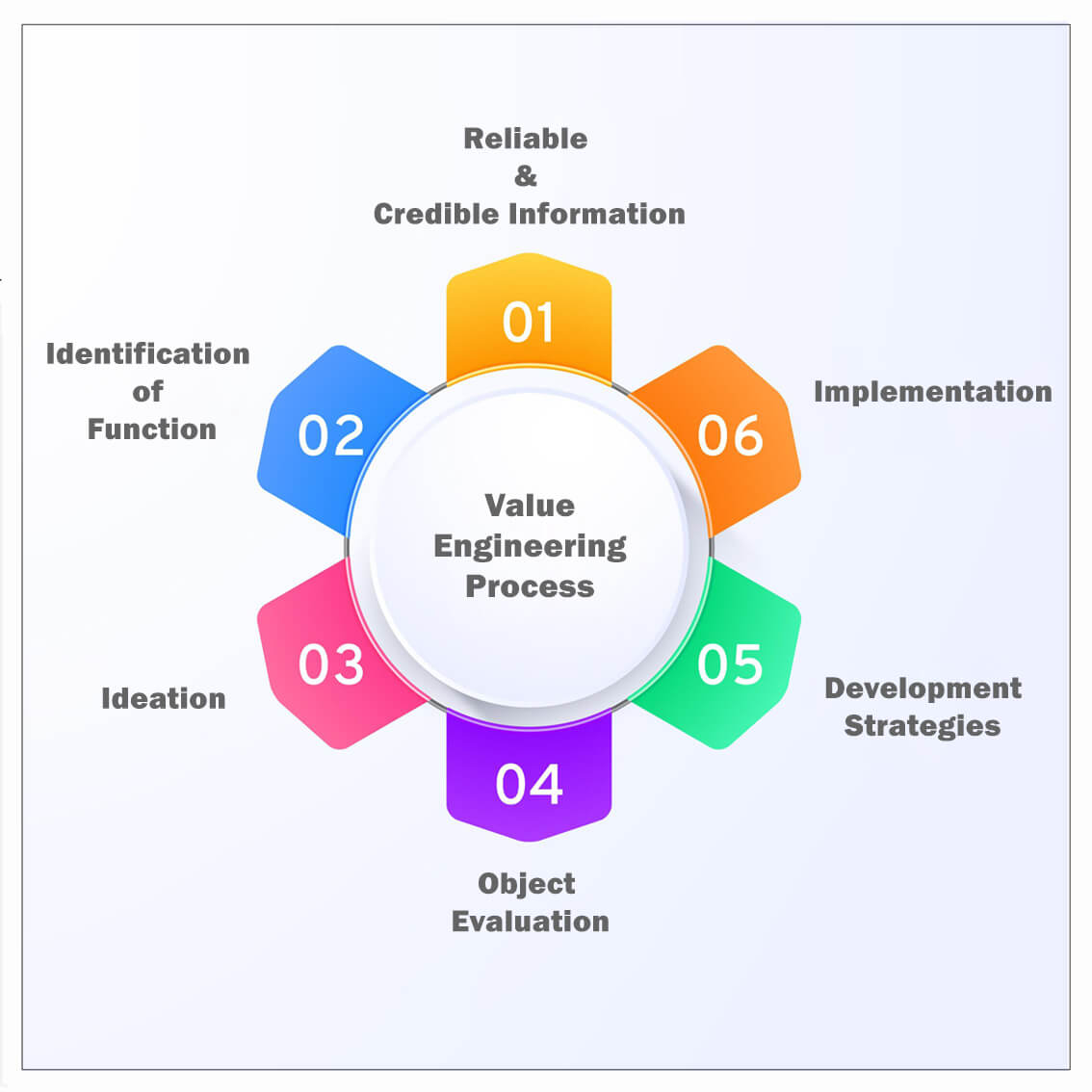

Value Engineering

Value engineering (VE) systematically analyzes the functions of various components and materials to lower the cost of goods, products and services with a tolerable loss of performance or functionality. Value, as defined, is the ratio of function to cost.

3D Prototype Testing

Prototype testing is a crucial step in product development, enabling teams to test early versions of a design to evaluate functionality, usability, and user experience. Prototype testing also helps manufacturers determine whether a particular manufacturing process or material works well for their application.