Table of Contents

Toggle3d printing and it’s usage in the making of large abstract geaometrical models

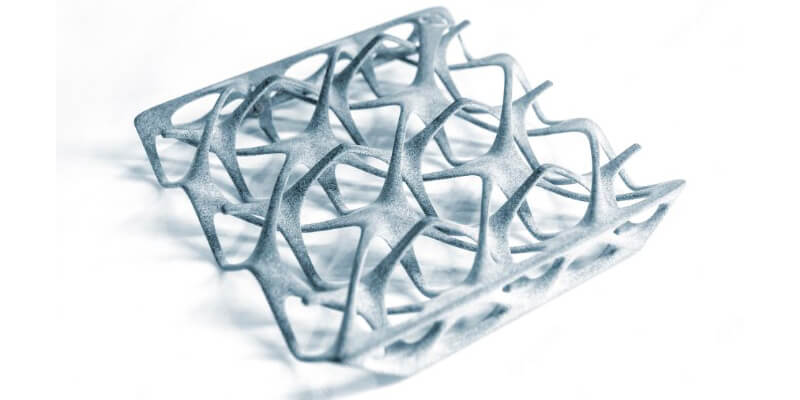

Large abstract geometric models are becoming increasingly popular in the field of 3D printing due to their versatility and the endless possibilities they offer. These models are often used in architecture, product design, and art, but their applications are not limited to these fields. With 3D printing technology, it is now possible to create complex shapes and designs that were previously impossible to produce using traditional manufacturing methods. One of the major advantages of using large abstract geometric models in 3D printing is the ability to create unique and customized designs. This is particularly useful in architecture, where buildings can be designed to fit specific sites and meet the needs of their occupants.

With 3D printing, architects can create intricate and complex designs that are not only aesthetically pleasing but also functional and efficient. The ability to customize designs according to specific requirements is a game-changer in the field of architecture. In product design, 3D printing allows for the creation of prototypes and small production runs, which can be used to test and refine designs before mass production. This not only saves time and money but also ensures that the final product meets the desired specifications. The use of large abstract geometric models in product design allows designers to create products that are not only visually appealing but also functional and durable.

Another advantage of using large abstract geometric models in 3D printing is the ability to create lightweight structures that are strong and durable. This is because 3D printing allows for the use of materials that are lightweight and strong, such as carbon fiber and titanium. These materials can be used to create structures that are both strong and lightweight, making them ideal for use in aerospace and other industries where weight is a critical factor.

The use of 3D printing in these industries has the potential to revolutionize the way we design and manufacture products. Overall, the use of large abstract geometric models in 3D printing is an exciting development that has the potential to revolutionize many industries. As 3D printing technology continues to evolve, we can expect to see even more innovative designs and applications in the future. The possibilities are endless, and the only limit is our imagination.

This technique allows for the creation of complex and intricate designs that would be difficult or impossible to produce using traditional manufacturing methods. Additionally, 3D printing can be more cost-effective and efficient for small-scale production runs. However, it is important to note that the quality and strength of the final product can vary depending on the type of material used and the printing process employed. As with any manufacturing process, careful planning and attention to detail are crucial for achieving the desired results.